Infinity meets reality

Vat Polymerization

Evonik is an innovation leader in ready-to-use photo-resins, additives and other components for additive manufacturing, which will help you to harness the full power of photo-curing 3D printing technology.

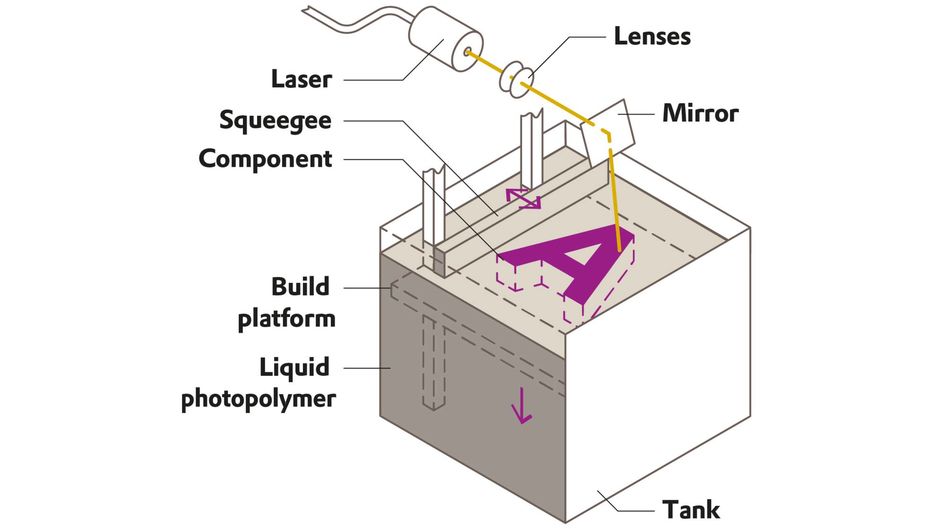

The construction platform is submerged step by step into a tank full of light-sensitive liquid plastic (photopolymer). In each step, mirrors are used to guide a laser beam to the points where it hardens the plastic. The finished component is lifted out of the tank. Depending on the printing method used, the component then has to be hardened further and the support structures, which are printed along with the part, are removed.

Cubicur's patented Hot Lithography technology enables the processing of highly viscous resins. A special heating and coating mechanism produces particularly tough and temperature-resistant polymers.

At this technology's core lies a specially developed, patented heating and coating mechanism. This mechanism is capable of safely processing even highly viscous resins and pastes at working temperatures of up to 120 °C with the utmost precision.

Elevated temperatures do not only affect the viscosity of a resin, but also its stability and reactivity. Hence, a precise process handling and control is necessary to avoid unintended polymerization and consequently, the degradation of the material. Thus, the temperature of all process elements can be precisely controlled.

Digital Light Processing is a variation of SLA, which makes use of a projector instead of a laser. By doing so, DLP allows for curing an entire layer at once, making it significantly quicker than most SLA printers. DLP printers are mostly bottom-up (projector is located on the bottom of the vat and build platform goes up), however a few DLP systems are now available as top-down (projector on top of the vat and build platform goes down). Because top-down photopolymer platforms allow for the larger vats, and DLP are typically faster than SLA, DLP top-down printers offer among the highest throughput currently available for vat photopolymer systems.

INFINAM® photopolymers are typically optimized for DLP printers, as on top of high printing speed and high throughput necessary for industrial-scale production, DLP technology is the most versatile technology and allows for printing a wide range of materials, including soft elastomers.

Stereolithography (SLA) was the first rapid prototyping process and today still is one of the most widely used rapid prototyping technology. It can produce highly accurate and detailed polymer parts. Evonik is a leading manufacturer of modified resins for 3D printing, which will help you to harness the full power of the SLA technology. This is the prerequisite to leave rapid prototyping and enter rapid manufacturing.

The technique of stereolithography has been known for a long time and features a very high accuracy of the 3D printed object. It results in gorgeous looking models with impeccable surface quality. So it comes with no surprise, that typical applications in the industry include modelling Formula 1 racecar parts for wind tunnel testing. More mundane applications include the manufacturing of individualized hearing aids and dentures or investment casting in jewelry and arts.

SLA converts liquid materials into solid parts, layer by layer, by selectively curing them by vat photopolymerization. To initiate the curing process, a highly focused UV laser traces out successive cross-sections of a 3D object in a vat of liquid photosensitive polymer. The photopolymer hardens instantly when the UV laser touches it, forming the first layer of the 3D-printed object. Once a layer is completed, the platform is lowered by a distance equal to the layer thickness. The next layer is formed on top of the previously completed layer. This process is repeated until the build is complete. Afterwards, the 3D printed object has to be freed from possible support structures. Usually it is baked in a UV oven as well, to complete the polymerization.

OUR READY-TO-USE PHOTOPOLYMERS

|

Product |

Technology |

Properties |

|

HL |

flexible |

|

|

DLP |

flame retardant |

|

|

SLA/DLP |

rigid |

|

|

SLA/DLP |

high strength |

|

|

SLA/DLP |

high toughness |

OUR PORTFOLIO OF ADDITIVES AND COMPONENTS

|

Product |

Technology |

Properties |

|

SLA/DLP |

Dispersants - Improve impact resistance or structural toughness |

|

|

SLA/DLP |

Dispersants - Improve impact resistance or structural toughness |

|

|

SLA/DLP |

Nano composites to improve edge sharpness and fracture toughness |

|

|

SLA/DLP |

Nano composites to boost mechanical properties |

|

|

SLA/DLP |

Reactive modifiers to improve fracture toughness and give a thermoplastic look and feel |

LET'S EXPLORE YOUR NEXT 3D APPLICATION TOGETHER!

The better we know you, the faster we can support you!

Podcast subscription

Listen to our exclusive podcast "Unbounding 3D printing at scale" by subsribing to our newsletter.